TracPipe: The Better Option

Written by Marty Hammersly

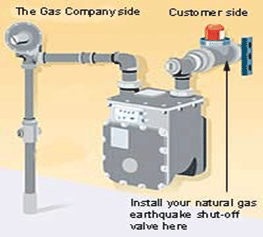

According to National Association of State Fire Marshals, CSST or TracPipe was developed in Japan in the 1980’s due to the large number of earthquakes.  Before and during the 1980’s, black iron pipe was being used and would easily break during an earthquake causing gas leaks that would ignite fires creating further destruction. TracPipe is a flexible system which allows for seismic activity without a gas leak. Adding the Seismic Valve (shown left) which will shut the flow of gas to the building with TracPipe will further reduce the risk of fire ignition after an earthquake.

Before and during the 1980’s, black iron pipe was being used and would easily break during an earthquake causing gas leaks that would ignite fires creating further destruction. TracPipe is a flexible system which allows for seismic activity without a gas leak. Adding the Seismic Valve (shown left) which will shut the flow of gas to the building with TracPipe will further reduce the risk of fire ignition after an earthquake.

In 1989 the American National Standards Institute created specifications for Interior Fuel Gas Piping utilizing TracPipe in the United States. By 1990 TracPipe was made available for sale and to this day continues to be the popular option.

Some interesting features of TracPipe are:

- Piping contractors are able to reduce labor and increase productivity since it is much easier to run TracPipe than black iron pipe. Example: TracPipe bends easily into an “S” curve where black iron pipe needs to be cut several times with elbow joints to create that same curve.

- TracPipe is wound in spools for easier transport to the job. No more bulky 21 foot lengths of black iron pipe strapped to your truck.

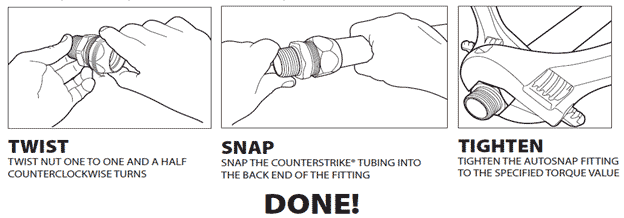

- TracPipe has unique fittings. They have either a split ring or a snap ring which, when tightened, make a seal tight connection. No need for cutting,threading or pipe dope.

The most common aboveground install with TracPipe is the Series. This consists of a main trunk with tees feeding the appliances. The Parallel System utilizes a manifold. Off the manifold, the individual appliances are fed. When installing either the Series or Parallel System, follow the manufacturer’s recommended specifications (see chart below) for proper support.

Piping Size Spacing of Supports |

For Horizontal |

| 3/8 inch | 4 feet |

| 1/2 inch | 6 feet |

| 3/4 inch | 8 feet |

| 1 inch | 8 feet |

| 1 1/4 inch | 8 feet |

| 1 1/2 inch | 8 feet |

| 2 inch | 8 feet |

For vertical runs, spacing of supports is not to exceed 10 feet, but make sure you check local code in your area. Remember, it is also important to protect any exposed stainless steel with a self-bonding silicone tape.

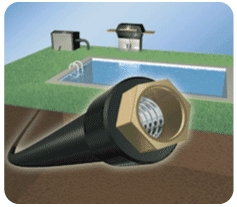

When installing TracPipe underground, it must be sleeved with a non-metallic water tight conduit since no fittings are permitted underground. When the installation requires running under a building most codes require the sleeve to be vented and must be able to withstand a heavy load. You can also use PS-II to accomplish this. The PS-II is designed to vent underground. Install the PS-II in a trench to the proper depth based on your local codes.

Most burial without concrete are a minimum of 18” deep. Whatever your installation (above ground or below ground) always remember to follow codes NFPA 54 & 58 as well as your local codes. Whether it is new or existing construction, TracPipe is a safe and reliable method of piping in today’s market.

Like this Article? Why not Share!